alright, day two.

i had just left the rear assembly under the car last night so today that was first on the to do list. it was a bit of a struggle but i got it pulled back far enough for me to work under the car.

the assembly all together on wheels moves around kinda like a hand cart but with no wheels and tires on the car its a bit stuborn, you can have the rubber on with out having hte car jacked sky high if you want to roll it out.

the main thing that i ran into that if i could, would do different next time is to either remove the torque tube from the rear completely or to at least take off the bit were the speedometer cable screws into the TT.

the rear was covered in dirt and im hopefully going to sell it all together so it just seemed easier to leave it bolted together. and my speedometer sending unit was fairly seized up so it stayed and the line got cut.

the reason i note these two things is when you go to roll or push the axel back the bell of the tt and the speedo bit get caught on just about everything when you try to pull it threw the X member. i ended up crawling under the car and holding it up with my hand and sticking a scrap of lumber under it to keep it at the correct height then went back to pushing the axle back. it took a couple of times back and forth but it worked. it sounds easy, but it was a little frustrating.

aaaaaanyhow...

with it out of the way behind the car i gathered up my tools for the day.

i think thats most of it, along with some ear protection and a broom. id recommend some safety glasses or the like also.

the instructions are pretty sparse so i didnt want them floating away, i held them down with my second favorite tool.

this would be my first :)

any how i set to measuring up were i need to make my holes. there seem to be 28 that need drilled but the directions tell you were to put about 2 per side of them. cute right?

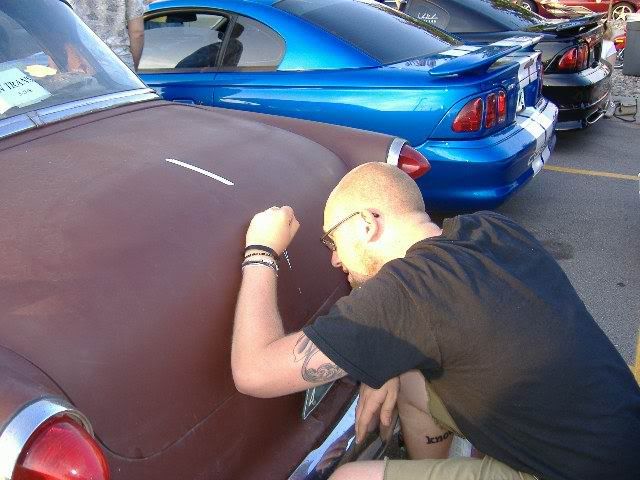

i measured roughly were the rear mount would land and tapped it up. i figured that sharpie on blue tape would be a whole heck of a lot easier to see then any sort of markings i could think of to show were i need to drill.

the 'instructions' give you measurements on were to place a hole on one hole of each mount. i held them up where i figured they needed to go and marked the centers of the holes the best i could. i could have done a better job looking back but im not realy sure how.... anyways...

i took favorite tool #2 and center punched were i would need to drill my holes. i made the X's on the tape fairly large so id be able to see were center was located if the tape ripped a bit. after that i went threw and drilled pilot holes for all 9 holes for the side.

spending the extra money on good bits was worth it but i still snapped two just from being at such a funny angle drilling the holes :S

i will make note that on the rear hangers i did the measuring on the outside of the rail because the channel of the rail has the open side facing the inside and the bracket uses spacers to make it work. so it was the only way i could mark directly threw the bracket.

i also pilot drilled from the outside, with the smaller bit i had room for my fat hands and even fatter drill between the fender and body/rail to get it done. however, i did drill the full size holes from the inside out as there is waaaay more room and the drill bit was to big to fit.

its a funny spot so i had to pull a 'pillow' over for me to rest my shoulders/head on so i could see what the heck i was doing.

the holes over all werent to big of a pain, i attempted taking my time and sprayed it with wd40 a few times to help the chips move out of the way. this is were i will say some saftey glasses/goggles would be a good idea. your in all sorts of funny positions with chips flying in your face doing this. i only finished the passenger side today so when i get on the other side i will most def have something more then my glasses protecting me.

so with holes drilled i bolted the brackets on. this is the front spring mount. i think 3 out of the 6 holes lined right up and the other 3 i needed to run the drill back threw the hole threw the bracket to get it all just right. i was off a teeny bit sometimes and other times about a 1/4 of the width of the bolt. again not sure how i could have gotten things lined up better when marking other then doing two holes and drilling the rest of them with the bracket on but that seems like a good way to gnar up your bracket.

and yes, i did measure, and re measure about a dozen times before drilling anything so im thining the bits just walked a bit when i was putting holes in, paired with being a titch off i was definantly off a bit.

i had previously un packed everything and figured out what bags of bolts go with what so when i got to it today i was able to sort everything out per piece pretty easy.

here is the rear spring hanger with the shackle bolted to it. i pressed the bushing in by hand and then used a 6 pound hammer and a vice to get the bolt threw it. in retrospect i should have left one side of the shackle un bolted as i ended up having to take it off to hang the spring and i dont want to take those nylon lock nuts off and back on more then once.

any how i got the rear hanger in place, put the spacers in and bolted it all up, had the middle hole not want to line up but it mostly ended up being a sequencing thing. id put the front and back bolts in and tightend them down before putting the spacer and bolt in the center hole and it misaligned it a bit.

put the front spring eye into the hanger no big deal.

they want you to bolt up your rear end next but seeing as i still need to rebuild it all it made more since to leave it out and wait till its ready to go, less moving that heavy sob for me always sounds like a good idea. ill lift it up onto a big steal welding table and start tearing into that in the next week or two.

rear hanger connected.

you can kinda see how the bracket tucks up into the frame here, you can also see that the bottom of the shackle isnt totaly bolted together. the nuts are just barely sitting on the bolts so they are not touching the nylon so when i go to put the new 9 inch in ill have brand new nuts.

i try to mix up big dollar stuff with 'free' stuff, big and little stuff, and important but cant see it and non important but is way visable when i build. i feel like it keeps some fun in the build, you dont get hit with all this $$$$ stuff back to back, you get a breather from the hard stuff while messing with easy stuff but still make progress, and when you do something little that shows it keeps the flame alive for the project.

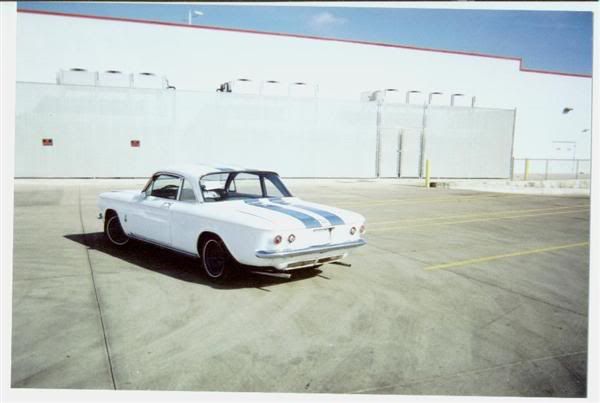

i was walking back from watering a tree, haha, and found this old moon cap so i thought id see if it was the right size/shape that i thought it was. it fits!

washed it up a bit and im super stoked! im going to run 40 ford caps but hadnt fully pictured it in my mind yet. i looked over at that wheel/cap probably 30 times and smiled while working today haha.

over all this side took me roughly 4 hours from the time i started measuring to when i bolted up the last bit. a plus side of working out of a farm shed is few outlets, hardly even a cell connection let along a land line, no tv, no ac, no couch, no distractions. just work on the car and listen to the radio.

my back is all sorts of tight and kinked up and ive got a very busy week at work ahead of me so ill let myself recover and hit it again maybe wednesday or thursday night. then with that all done ill get the gas tank flushed, cleaned and all that things going to need. under coat the floor above the gas tank, start into rebuilding and re gearing the 9 inch that aught to take up the next week or two and then itll be time to run my dash to nebraska to get my dash painted up all shiney like :)